SacO2 Microsac Information

Innovative Operating Principle

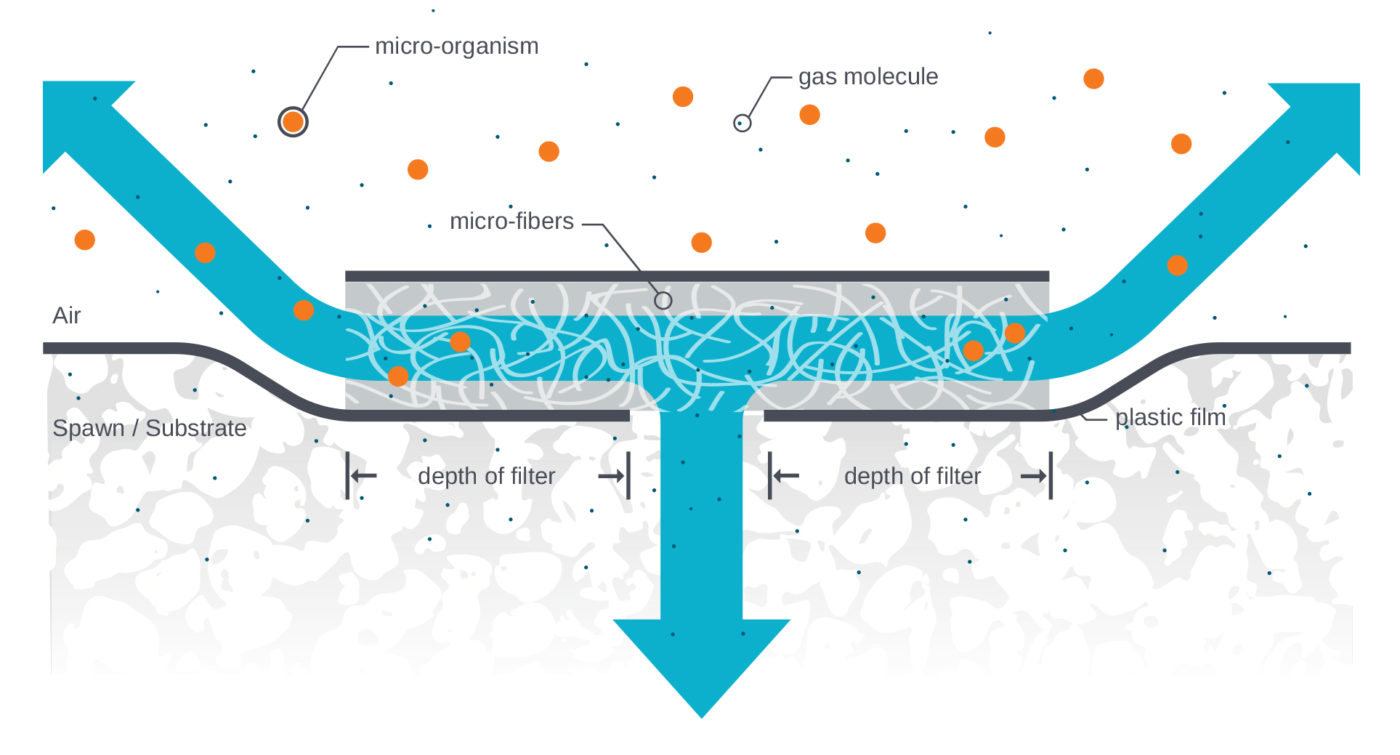

SacO2's Microsac Filter stands out with its revolutionary depth-filtration system. Unlike traditional spawn and substrate bags that use surface filtration, Microsac Filters leverage a unique system of randomly arranged fibres, trapping microorganisms effectively. This system, akin to the HEPA-filter technology, ensures fluent gas exchange without creating dry zones below the filters, while providing robust protection against pests and diseases.

Technical Advancements

Microsac bags are designed with exceptional qualities:-

Autoclavable: Enduring temperatures up to 124°C (255°F), suitable for sterilization processes.

-

Enhanced Gas Exchange: Filter strips run the entire length of the bag, ensuring optimal gas distribution.

-

Durability: Rigorously tested for strength post-heat treatment and handling.

-

Visibility: The bag's material and filter design allow for excellent visual quality control.

-

Flexibility and No Dry-out Zones: Customizable bag lengths and filter distribution tailored to specific gas exchange requirements, while minimizing substrate dehydration.